Are you interested in the stabilising system of a cocoa powder machine? Based on the latest insights in the handling of cocoa powder, Teckru can supply a very efficient stabilising processing system. Adding our powder stabilising unit to the TCM mill completes the system, in which the powder production process is fully enclosed. Kibbled cake from the presses can be packed as stabilized powder in just a few hours. Since powder is at the endpoint of the cocoa factory product flow, it is of crucial importance to attain the desired fineness, consistency, and colour. The complete system will ensure that cocoa powder can be bagged and traded for its full potential.

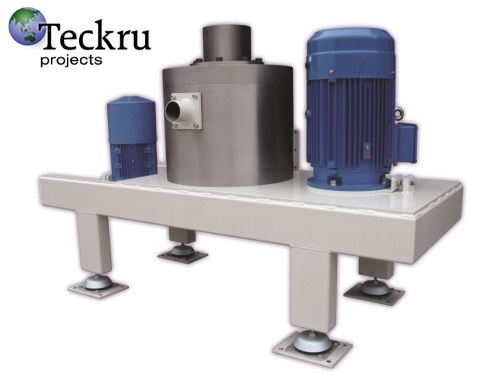

Powder classifier mill by our cocoa powder machine

Replacing the classic pin mill, the classifier mill already has a strong presence in the cocoa industry. It combines milling and classifying in one machine and can consistently reach the powder fineness that the industry demands. To separate the fine product from the air flow we use a filter vessel. The air flow is cooled with a heat exchanger/chiller combination, which greatly improves the cocoa product behaviour.

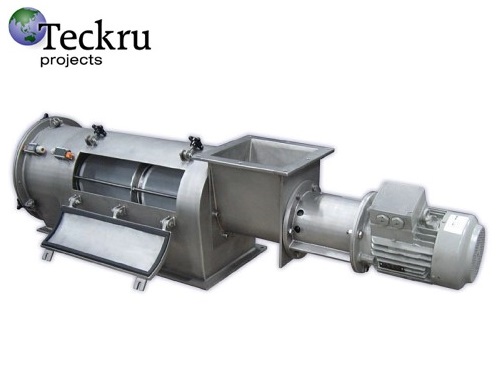

Cocoa powder screener by our cocoa powder machine

Although our classifier mill has integral screening functionality, it still advisable to process the cocoa powder with a dedicated screener. We can supply cyclone powder screeners that handle this task with great accuracy and reliability. Any impurities are automatically removed from the product flow. Aside from cocoa powder machine we offer a variety of other products such as:

Order your powder machine today!

Do you want to buy a cocoa powder machine? Then browse the different models that we have available and choose which one appeals to your needs. Request a quote! Do you want to know additional information about our other processing products? Then feel free to contact us. We are happy to assist you in any way that we can.

Butter pressing systems

As one of the few companies in the world we supply the cocoa industry with state-of-the-art cocoa butter presses. Presses are used for pressing the butter content out of a batch of cocoa liquor, then discharging cocoa cakes with the desired leftover fat content. The leftover fat content is typically 10 to…

Other processing products

For continuous filtration of pressed liquid butter. It consists of a vessel containing specially designed filter candles and utilities. The filter material has been selected specifically for the processing of cocoa butter. The system features a cleaning facility that can be started when desired, to bring the filter back to optimal production…